Process Analysis: Run time and Capacity

In process analysis, once we have mapped the process, the next step is to focus on run time and capacity and other key metrics for each stage. These metrics allow us to optimize the process and make data-driven decisions.

Measuring Run Time

One of the easiest to measure is run time—the time it takes to process one unit at a specific step. It’s important to note that run time is time per unit, not just total time.

Let’s say we measure the run time for each step of our process (in hours per unit):

| Step | Process | Time (hr/unit) |

|---|---|---|

| 1 | Cut | 3.2 |

| 2 | Build 1 | 5.0 |

| 3 | Build 2 | 4.0 |

| 4 | Paint | 2.5 |

| 5 | Pack(W1) | 6.4 |

| 5 | Pack(W2) | 4.0 |

Calculating Capacity

Capacity is the maximum number of units that can be processed by a resource in a given time period.

For example:

- Step 1’s run time is 3.2 hr/unit, meaning it takes 3.2 hours to make one unit.

- In one hour, Step 1 can make: $1 / 3.2$ units.

- In two hours, Step 1 can make: $(1 / 3.2) \times 2$ units.

If we want to calculate Step 1’s weekly capacity (assuming 5 workdays per week and 8 hours per day):

$$

\text{Capacity} = \frac{8 \text{ hr/day} \times 5 \text{ days/week}}{3.2 \text{ hr/unit}} = 12.5 \text{ units/week}

$$

General Formula:

$$

\text{Capacity} = \frac{\text{Total Available Time}}{\text{Time Required per Unit}}

$$

Note: If there is no setup time, the “time required per unit” is the same as the run time. We will explore the impact of setup time in the next post.

Two ways to increase capacity:

- Increase total available time (e.g., add shifts, work overtime).

- Reduce time required per unit (e.g., improve efficiency, upgrade equipment).

Calculating Capacity for All Steps

| Step | Process | Time (hr/unit) | Capacity (units/week) |

|---|---|---|---|

| 1 | Cut | 3.2 | 12.50 |

| 2 | Build 1 | 5.0 | 8.00 |

| 3 | Build 2 | 4.0 | 10.00 |

| 4 | Paint | 2.5 | 16.00 |

| 5 | Pack(W1) | 6.4 | 6.25 |

| 5 | Pack(W2) | 4.0 | 10.00 |

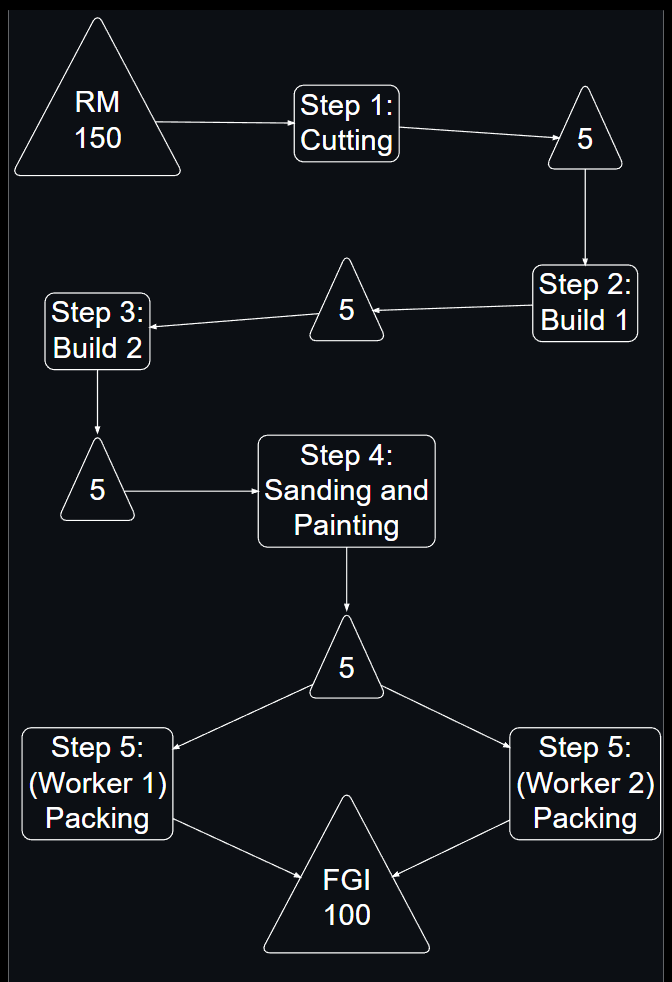

Finding the Whole Process Capacity

To calculate the overall process capacity, we need to understand how to handle parallel steps and series steps.

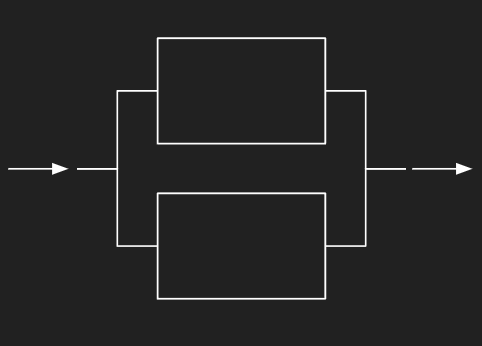

Parallel Step

When two or more resources work in parallel on the same stage, their capacities are additive. Think of it like two cashiers in a store—if each can serve a certain number of customers per hour, together they can serve more customers in the same time. That’s why, in parallel setups, the combined capacity is found by summing each resource’s capacity. For Step 5:

- Pack (W1) capacity = 6.25 units/week

- Pack (W2) capacity = 10.00 units/week

- Total = 16.25 units/week

To find the equivalent run time for the parallel stage:

$$

\text{Run Time} = \frac{1}{16.25} \ \text{weeks/unit} \approx 0.0615 \ \text{weeks/unit}

$$

If a week is 40 working hours:

$$

0.0615 \times 40 \approx 2.46 \ \text{hours/unit}

$$

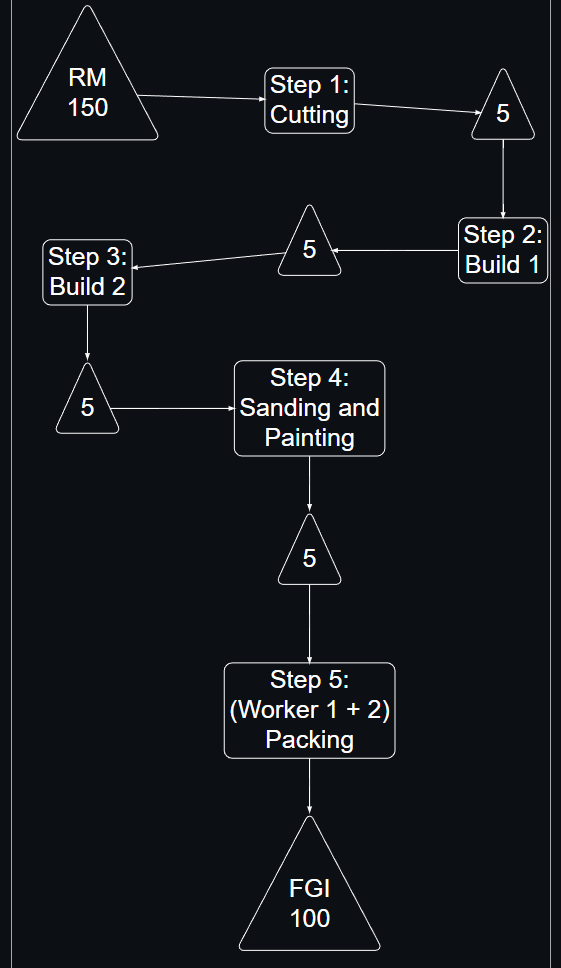

The exact value is 2.461538 hours/unit. Using this, we can simplify the diagram and present the table more cleanly:

| Step | Process | Time (hr/unit) | Capacity (units/week) |

|---|---|---|---|

| 1 | Cut | 3.20 | 12.50 |

| 2 | Build 1 | 5.00 | 8.00 |

| 3 | Build 2 | 4.00 | 10.00 |

| 4 | Paint | 2.50 | 16.00 |

| 5 | Pack (W1+W2) | 2.46 | 16.25 |

Series Step

A series step is when multiple process steps are connected sequentially, and every unit must pass through each step in order. Think of it like traffic moving through a single-lane road at several points—overall speed is determined by the slowest section. Step 1 through Step 5 in our example form a series step, and the overall capacity of the process is limited by the step with the lowest capacity. In our example:

- The lowest capacity is 8 units/week (Step 2: Build 1).

- Therefore, the entire process capacity is 8 units/week.

- This limiting step is called the bottleneck—the resource that constrains overall production.

So, the overall process capacity—considering both parallel and series steps—is 8 units/week.

Next Steps

How can we increase the capacity of this process? Now that we’ve:

- Mapped the process,

- Measured run times, and

- Calculated capacities,

…we’re ready to explore practical methods for increasing capacity in the next post.