Process Analysis: Cranberry Case 1

In our previous posts, we explored the fundamentals of supply chain management, focusing on what capacity is and the various strategies you can use to increase it. However, a crucial element was missing from the equation: demand.

This post will bridge that gap. We’re going to dive into how you can integrate demand forecasting and management into your entire supply chain process, transforming a linear model into an interconnected, responsive system. To illustrate this powerful concept, we will analyze the classic and highly influential National Cranberry Cooperative Case Study.

The Core Problem

The National Cranberry case study is a prime example of a company grappling with a significant challenge: how to increase the capacity of its processing plant to handle the seasonal influx of cranberries while simultaneously reducing operational waste. The central problem revolves around minimizing expensive overtime for factory workers and eliminating costly idling for truck drivers waiting to unload their product.

The Two Types of Cranberries

There are two types of cranberries:

- Dry Cranberries: These are hand-picked from the bushes. This traditional method results in berries with less damage, allowing them to be stored for longer.

- Wet Cranberries: These are harvested by flooding the bogs and mechanically shaking the berries from the bushes. Since cranberries have a pocket of air inside, they float to the surface for easy collection. This method yields more berries but can cause some damage and shortens their shelf life.

The Cranberry Processing Flow

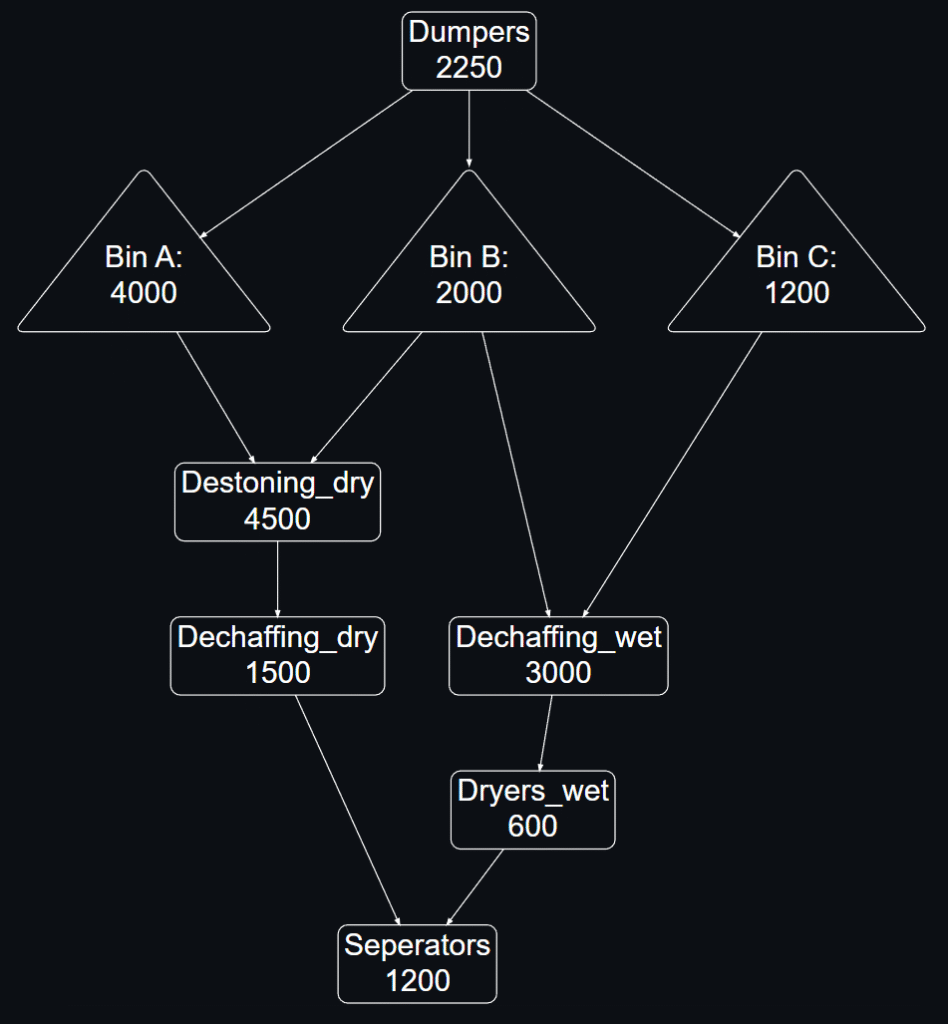

If I summarize the process, it would be like this. The processing of cranberries at the National Cranberry facility follows a specific sequence.

- Arrival: Trucks arrive at the plant and unload the cranberries into dumpers, which act as a central receiving point. Truck arrivals occur from 7:00 am to 7:00 pm, a total of 12 hours.

- Temporary storage: From the dumpers, the berries are routed to one of three types of temporary storage bins:

- Bin A: A set of 16 bins (Bin #1 to #16) that are exclusively for dry cranberries.

- Bin B: A set of 8 bins (Bin #17 to #24) that can handle both dry and wet cranberries.

- Bin C: a set of 3 bins (Bin #25 to #27) that are exclusively for wet cranberries.

- Cleaning: The cranberries then undergo a two-step cleaning process in series:

- Destoning: A process to remove any stones or rocks.

- Dechaffing: A process to remove leaves, stems, and other debris.

- Separation: Finally, both types of cranberries move on to separators, which grade the berries based on quality into first, second, or unacceptable grades.

The capacities of each step (in bbls/hr) are denoted in the process diagram. Workers are only present at the dumper and bins from 7:00 am to 11:00 am. The rest of the processing steps begin at 11:00 am. This creates a staggered workflow that is important for managing the overall operation.