Process Analysis: Cranberry Case 3

Removing Idle Time

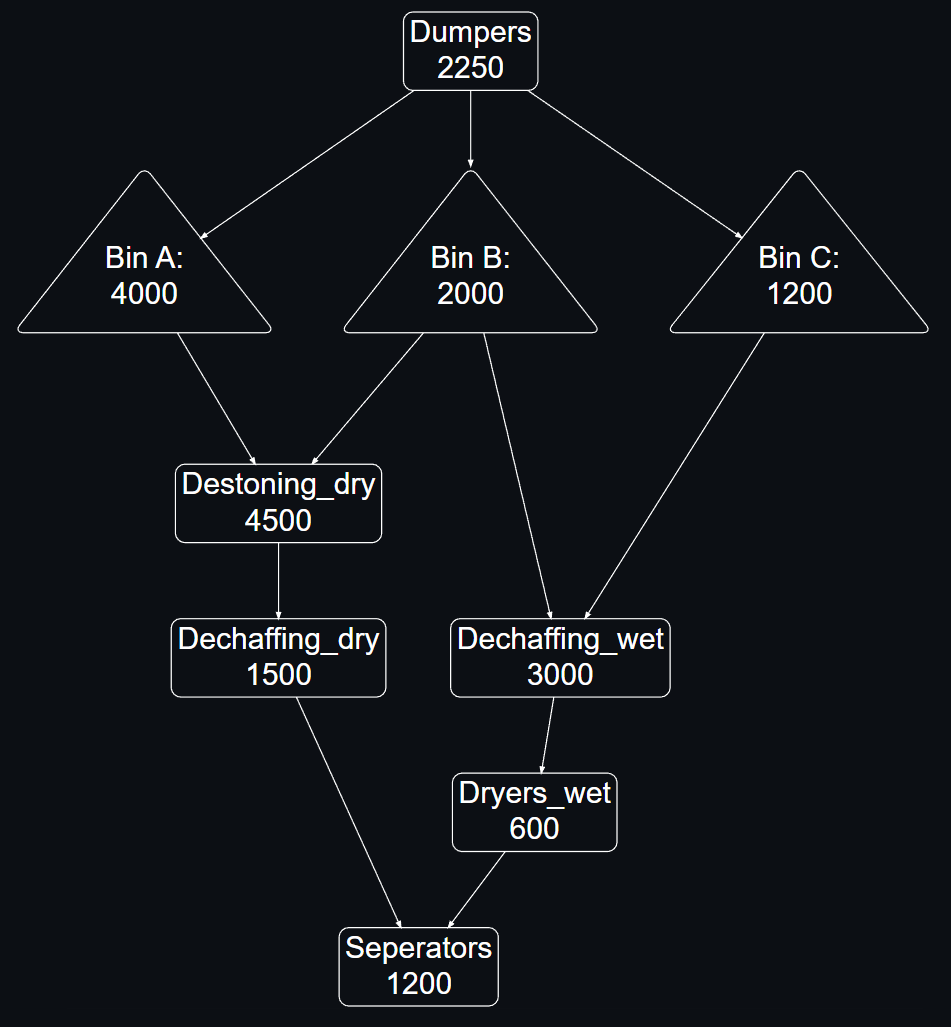

In our previous post, we identified the primary challenge at the National Cranberry processing plant: a severe bottleneck in the wet cranberry processing line because the truck arrival rate exceeded the plant’s capacity. Now, we will explore potential solutions, analyzing how different interventions can improve efficiency and reduce waste.

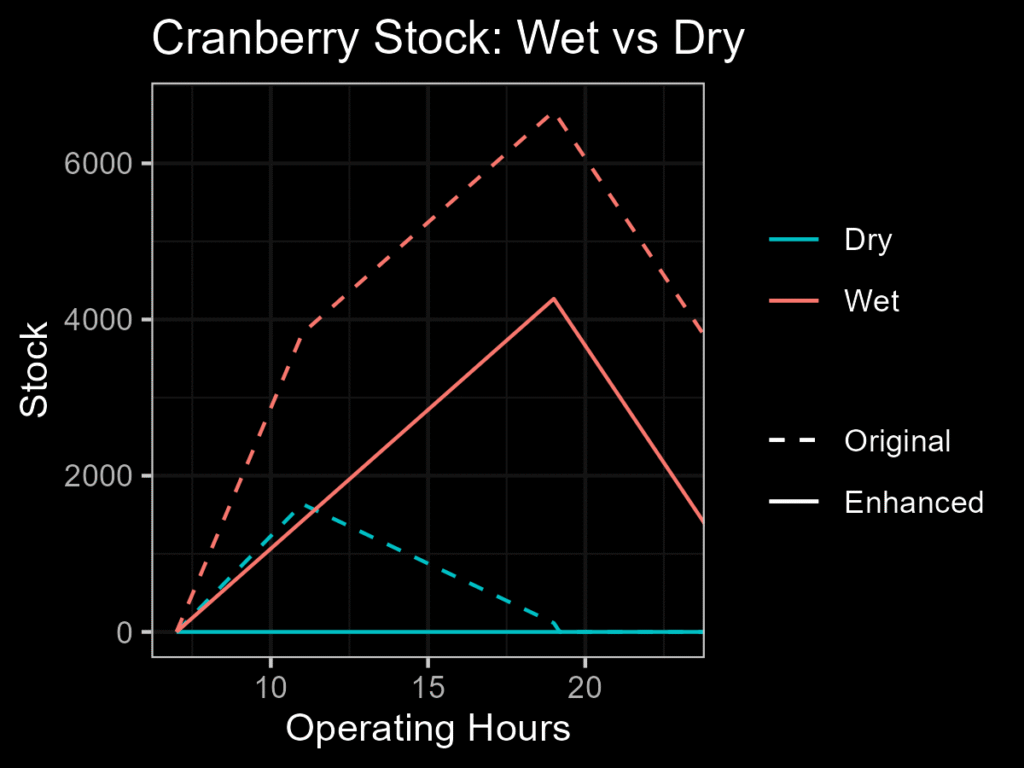

One potential solution is to eliminate the idle time from 7:00 am to 11:00 am and run the wet cranberry processing line at full capacity from the start of the day. Let’s analyze what happens in this scenario.

Since still, the arrival rate (955.49 bbls/hr) is greater than the processing capacity (600 bbls/hr), the inventory will still continuously increase throughout the day. The stock would increase at a rate of 355.49 bbls/hr (955.49−600). The total inventory in the bins at 7:00 pm would be 4,265.88 bbls (355.49 bbls/hr × 12 hours).

While this is a significant improvement (6,665.86 bbls → 4,265.88 bbls), the problem still exists. It would take the plant approximately 7.11 hours (4,265.88/600) to fully process the remaining total stock. This extends beyond the factory’s 11:00 pm shutdown time, meaning the plant would still discard a portion of the cranberries. To truly solve the problem, we must consider further solutions.

Note: The dry cranberry process can be handled without issue, as the remaining separator capacity of 600 bbls/hr (1200 bbls/hr total capacity – 600 bbls/hr for wet cranberries) is sufficient.

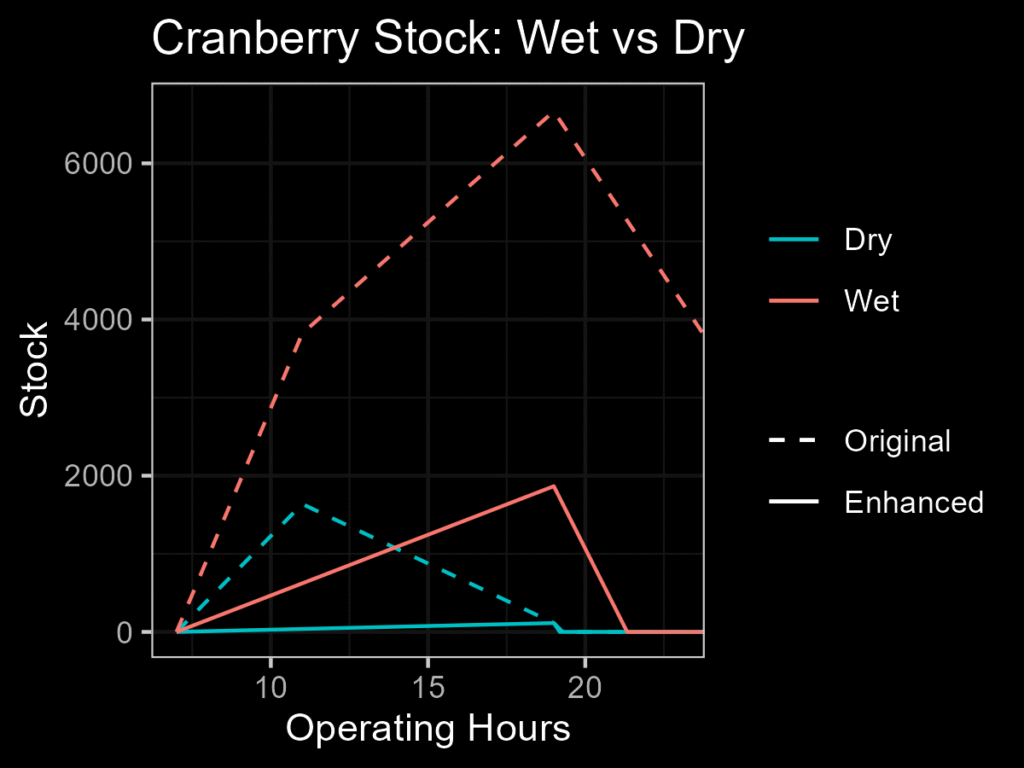

Increasing Dryer Capacity

What if the company invests in a new dryer, increasing the wet cranberry processing capacity by 200 bbls/hr from 600 to 800 bbls/hr?

In this scenario, the new dryer would reduce the rate of wet cranberries stock increase to just 155.49 bbls per hour (955.49−800). Over a full 12-hour operational period, the plant would accumulate a total inventory of 1,865.88 bbls (155.49×12).

The plant could fully process this remaining stock in approximately 2.33 hours (1,865.88/800). With truck deliveries stopping at 7:00 pm and the factory running until 11:00 pm, this amount of time would be well within the available hours, preventing the company from discarding any cranberries.

This investment would naturally reduce the available separator capacity for dry cranberries from 600 bbls/hr to 400 bbls/hr (1,200 total capacity −800 bbls/hr for the wet line). Over the 12-hour operational period, this reduced capacity would lead to a small accumulation of dry cranberry stock, which would increase to 113.88 bbls ((409.49−400)*12). However, this backlog can be processed in just 0.28 hours (113.88/400) after 7:00 pm, once truck deliveries have ceased. Therefore, with this strategic change, the plant can efficiently manage the flow of both wet and dry cranberries on average.

The final decision of whether to invest in the new dryer depends on a crucial cost-benefit analysis: does the value of the cranberries that the company would no longer discard outweigh the cost of investing in the new dryer? This is the fundamental trade-off that the company must analyze to make a sound strategic decision.

Reference:

National Cranberry Cooperative Case Study by J. Tucker, 1996, Harvard Business School.