Process Analysis: How to Increase Capacity

How Can We Increase This Process’s Overall Capacity?

In the previous post, we:

- Mapped the process

- Measured run times

- Calculated capacities

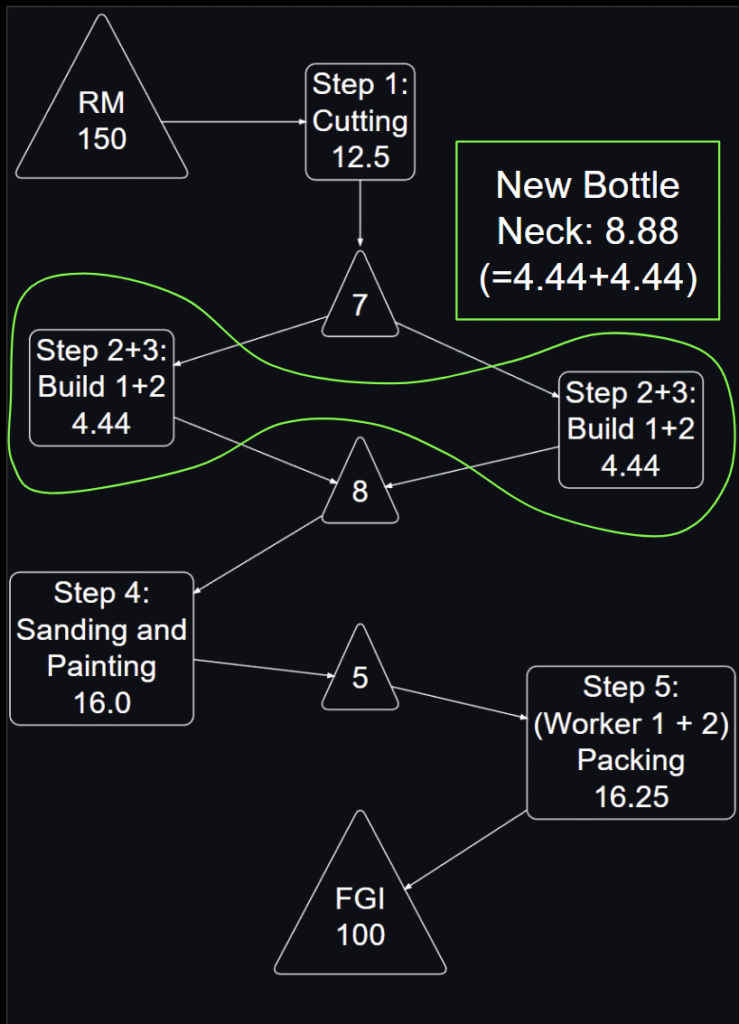

The process’s run time and capacity for each step are as follows:

| Step | Process | Time (hr/unit) | Capacity (units/week) |

|---|---|---|---|

| 1 | Cut | 3.20 | 12.50 |

| 2 | Build 1 | 5.00 | 8.00 |

| 3 | Build 2 | 4.00 | 10.00 |

| 4 | Paint | 2.50 | 16.00 |

| 5 | Pack (W1+W2) | 2.46 | 16.25 |

The overall capacity is 8 units/week because Step 2 (Build 1) is the bottleneck in this series of steps.

There are several practical strategies to boost capacity. Below are a few examples:

Method 1: Combine Roles Across Steps

Workers in Step 2 (Build 1 – assembling legs and bottom of the chair) and Step 3 (Build 2 – attaching armrest and backrest) are reassigned so that each person performs both Build 1 and Build 2 tasks. At the same time, we redistribute the 5 units of buffer stock between these steps—adding 2 units before Build 1 (increasing that buffer to 7) and 3 units after Build 2 (increasing that buffer to 8).

Assuming the run time for Build 1+2 is simply the sum of the original times—5 hr for Build 1 plus 4 hr for Build 2—we get 9 hr/unit. With 8 working hours per day and 5 days per week, the capacity for one worker is 4.44 units/week ((1/9) × 8 × 5). With two workers in parallel, the combined capacity becomes 8.88 units/week (4.44 + 4.44), making this the new bottleneck—slightly higher than the previous bottleneck capacity of 8.

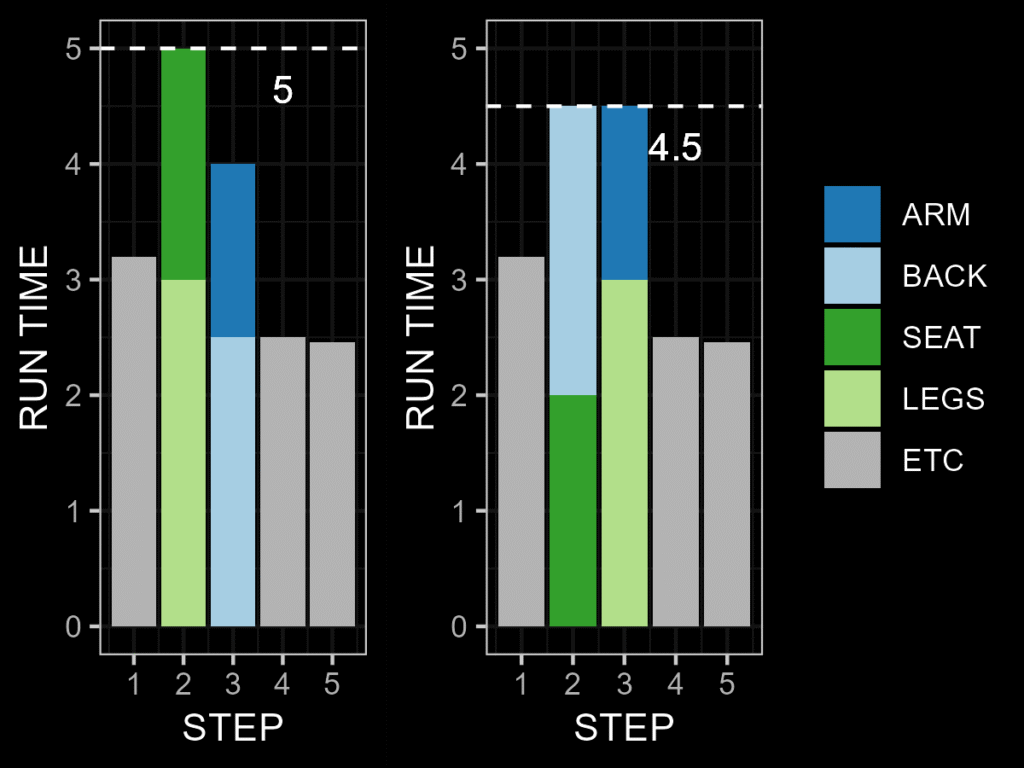

Method 2: Balance Tasks to Reduce Peak Run Time

Reducing the highest run time helps remove bottlenecks. Suppose that in Build 1 the seat assembly requires 2 hr/unit and the legs require 3 hr/unit. In Build 2, the arm assembly requires 1.5 hr/unit and the back requires 2.5 hr/unit. We can balance the workload by moving the back assembly from Build 2 to Build 1 and moving the leg assembly from Build 1 to Build 2. After this change, both Build 1 and Build 2 have a run time of 4.5 hr/unit. This reduces the bottleneck step’s run time from 5 hr/unit to 4.5 hr/unit, increasing capacity from 8 units/week (1/5 × 40) to 8.89 units/week (1/4.5 × 40).

Method 3: Move One Worker from Packing to Build 1

There are two workers in packaging: the first has a capacity of 6.25 units/week, and the second 10 units/week. If we reassign the first worker to Build 1, the capacity of Build 1 could increase significantly. If this raises Build 1’s capacity to 9.5 units/week, the overall process capacity rises to 9.5 units/week. If Build 1’s capacity exceeds 10 units/week, the new bottleneck shifts to the remaining packaging worker, whose capacity is 10 units/week.

Other Quick Options

- Add equipment or tools to speed up processing in the bottleneck step.

- Introduce overtime or additional shifts to increase total available time.

- Cross-train workers so they can support bottleneck steps during peak demand.

- Streamline workflow by removing unnecessary steps or combining operations.

- Improve quality at earlier stages to reduce rework at bottlenecks.